Beyond the Code Requirements of In-Service Welding

- Justin Bekker

- Oct 1, 2025

- 1 min read

Please visit PPIM's catalogue of 2025 conference papers for an article that I wrote on the extra considerations required for welding of an in-service procedure qualification record (PQR).

Abstract

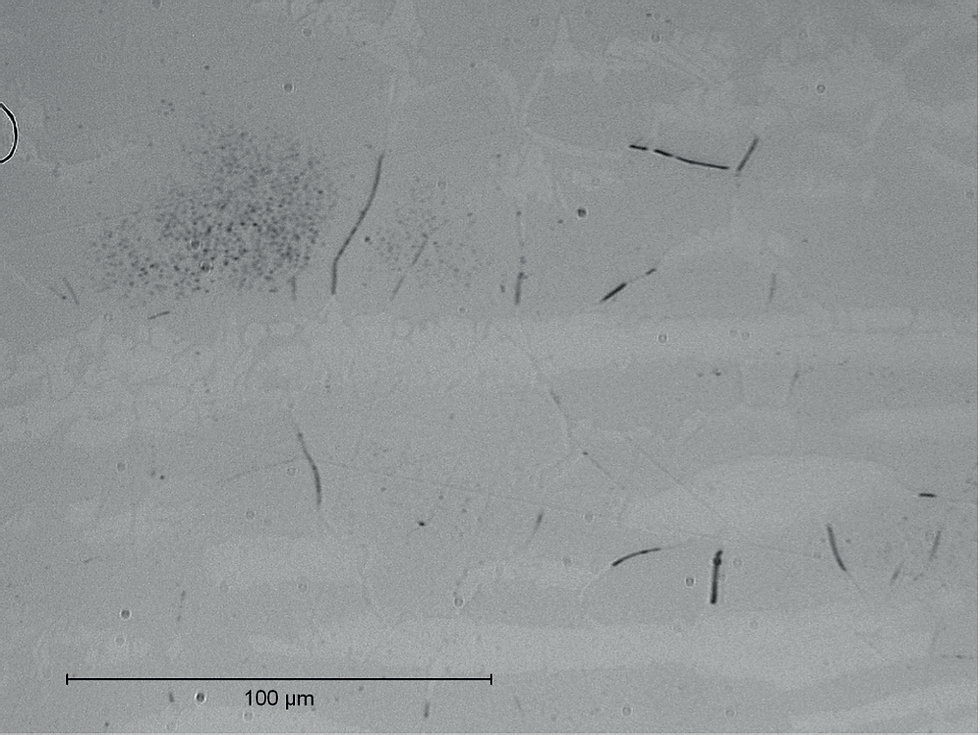

The in-service welding of pipelines i.e., sleeves and hot taps, presents unique challenges from accelerated cooling, residual stresses, and risk of burn-through. While adherence to relevant welding codes is essential, it may not be sufficient to ensure the weld integrity. This paper explores factors beyond code requirements that must be considered when qualifying welding procedures for in-service applications with fillet, groove and overlay welds. The typical standards that are followed are API 1104 [1], CSA Z662 [2], and ASME B31.3 [3] (which references ASME BPVC Section IX [4]). The essential variables of these codes are generally similar to ASME BPVC Section IX, with some additional requirements, such as closer attention to heat inputs, cooling rates, and the resulting hardness.

Standards require that the cooling rate and welding restraint be considered, but do not state specific requirements. Hardness requirements are specified but the hardness test locations are open to interpretation and higher hardness values are permitted if they can be justified. Further, methods for determining acceptable heat inputs for minimizing the risk of burn-through in a thin-wall pipe is not specified. These aspects of the codes that require consideration and determination of acceptable heat inputs are critical to ensure safety of the welding crew and long-term integrity of the in-service welds. This paper brings to attention these considerations and provides some best practices for addressing them.

Comments