Protection, Processes, and Positioning: Shielding gases used in stainless steel welding.

- Justin Bekker

- Oct 27, 2025

- 1 min read

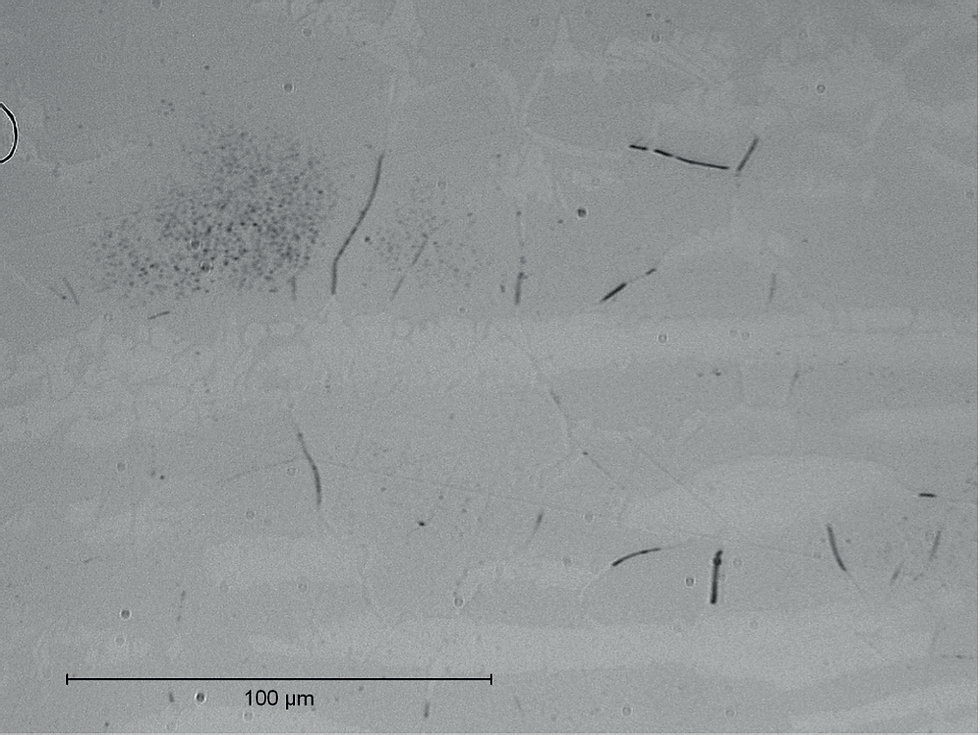

The metals in stainless steels like to oxidize (when iron oxidizes, we call it rust). The chromium in stainless steel has a relatively high potential to oxidize, which is why it is added to stainless steel. This oxide forms a protective coating on the outer surface, preventing further oxidation of the material beneath the oxide layer. When welding, the metal experiences a liquid stage, and if oxidation of the liquid occurs, this oxide forms impurities within the weld. Furthermore, it depletes the weld of chromium, so that the outer protective coating may not form. In addition to oxygen, other elements like nitrogen and hydrogen can form impurities, and deplete the metal of alloying elements.

This article discusses some aspects of shielding gas selection. The full article can be read at Stainless Steel World Americas' site.

Comments